The Ultimate Guide to Galvo Scanner Innovation and Its Numerous Uses

The Ultimate Guide to Galvo Scanner Innovation and Its Numerous Uses

Blog Article

Discovering the Benefits of Digital Galvo Scanners for Improved Performance

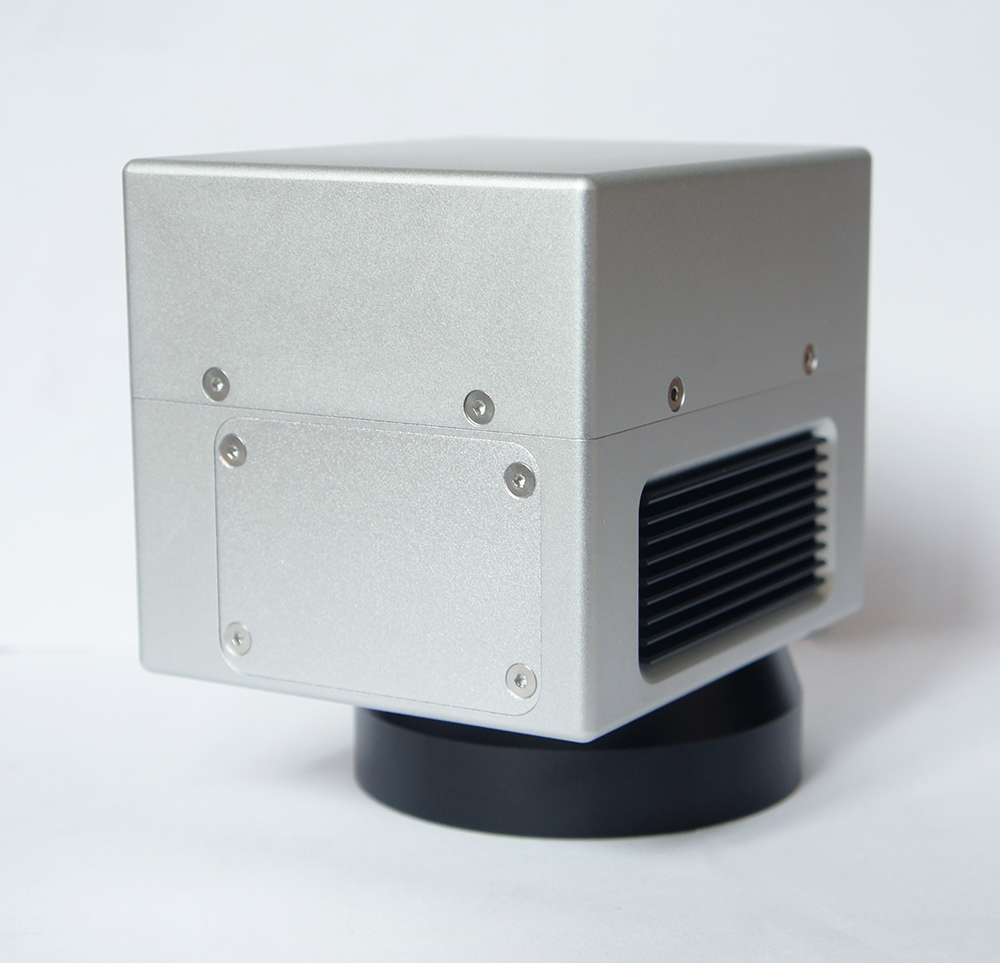

The integration of electronic galvo scanners is changing performance metrics in laser processing applications, characterized by significant advancements in accuracy and functional speed. These systems harness galvanometer-driven mirrors to attain unparalleled precision, while their quick repositioning capacities improve overall performance. Their adaptability throughout diverse materials and procedures underscores their importance in modern manufacturing. As sectors progressively seek cutting-edge services to maximize performance, understanding the complete spectrum of advantages provided by electronic galvo scanners ends up being essential. What effects do these developments hold for the future of laser technology and production practices?

Improved Accuracy and Precision

Digital galvo scanners have actually reinvented the field of laser processing by enhancing accuracy and precision in various applications. These innovative systems utilize galvanometer-driven mirrors to guide laser light beams with outstanding control, considerably minimizing the margin of mistake related to standard laser systems. This better precision is specifically advantageous in markets such as production, clinical device fabrication, and electronics, where tight tolerances and elaborate styles are crucial.

The ability to achieve accurate laser positioning permits finer outlining and boosted top quality in inscription, reducing, and noting procedures. Digital galvo scanners can implement intricate patterns with minimal deviation, guaranteeing that the end products meet strict specs. Furthermore, the real-time comments systems incorporated within these systems assist in continual changes, better boosting the total accuracy of laser operations.

Additionally, the high-speed action of galvo scanners allows constant performance throughout numerous products and thicknesses, decreasing the danger of defects. Consequently, manufacturers can achieve more reliable outcomes, leading to raised consumer contentment and minimized waste. In summary, the precision and precision offered by digital galvo scanners are pivotal in progressing laser processing technologies, making them indispensable devices across multiple fields.

Boosted Rate of Procedure

Frequently, the combination of galvo scanners right into laser processing systems results in a considerable rise in operational rate. Unlike typical stepper motors, which call for time to accelerate and slow down, galvo scanners utilize mirror-based systems that promote near-instantaneous movement.

Additionally, the high-speed operation of galvo scanners makes it possible for constant processing, lessening idle time and raising performance. The scanners can deal with complicated patterns and high-density layouts without sacrificing speed or high quality, making them excellent for applications such as engraving, cutting, and marking.

Flexibility Throughout Applications

Galvo scanners are increasingly identified for their versatility throughout a variety of applications in laser processing. These advanced tools allow specific laser beam control, making them suitable for varied jobs such as engraving, cutting, and noting on various materials, consisting of porcelains, metals, and plastics - Laser Galvo. The capability to swiftly reposition the laser beam of light permits elaborate designs and patterns, improving creative possibilities in industries ranging from producing to art

In addition to typical applications, electronic galvo scanners are also utilized in sophisticated areas such as clinical tool production, where precision is critical. Their ability to run at broadband while keeping precision makes them ideal for processes like laser welding and ablation. Moreover, their flexibility to various laser wavelengths and power setups ensures compatibility with various materials, broadening their application scope.

Furthermore, home the integration of galvo scanners with automated systems enhances their functionality, permitting seamless procedure in robot and manufacturing line settings. This adaptability not just enhances operations however additionally sustains personalized remedies customized to certain sector requirements. Eventually, the flexibility of digital galvo scanners positions them as important assets in modern laser handling modern technologies.

Cost-Effectiveness and Performance

Exactly how do cost-effectiveness and efficiency contribute in the adoption of laser technologies? The increasing need for rapid and specific handling in various sectors has actually catalyzed the combination of digital galvo scanners, which use both cost benefits and functional performance. These scanners streamline laser applications, minimizing material waste and reducing functional costs related to conventional techniques.

Digital galvo scanners enhance efficiency by enabling faster handling rates, which translates to shorter manufacturing cycles. This efficiency not only enhances throughput but also enables firms to meet tight deadlines without compromising top quality. Additionally, the reduction in power usage during laser operations adds to decrease utility prices, even more enhancing total cost-effectiveness.

In addition, the durability and dependability of galvo scanners minimize upkeep expenses, as they require less frequent servicing compared to various other laser systems. As businesses strive to remain competitive, the fostering of cost-effective solutions like electronic galvo scanners is essential.

Enhanced User Experience

The assimilation of electronic galvo scanners dramatically boosts the customer experience in laser applications, supplying operators with user-friendly my latest blog post controls and real-time feedback. This advanced technology allows for specific adjustment of laser beam of lights, allowing users to achieve detailed styles with very little effort (Laser Galvo). The intuitive user interface commonly includes graphical depictions of laser courses, simplifying the programming procedure and minimizing the discovering curve for new operators

Moreover, electronic galvo scanners provide quick action times, which improves process efficiency. Operators can make modifications on the fly, allowing for instant aesthetic feedback throughout the laser handling. This responsiveness not only enhances productivity however also promotes a much more appealing and interactive workplace.

In addition, the ability to easily incorporate with existing software program enhances compatibility and individual ease. Numerous electronic galvo systems sustain commonly utilized layout software, improving the shift from layout to execution.

Conclusion

In final thought, digital galvo scanners substantially boost performance in laser processing applications via boosted precision, raised functional rate, and versatility throughout various products. As technology continues to advance, the adoption of electronic galvo scanners is positioned to drive improvements in precision engineering and production practices.

Report this page